- High-Resolution Industrial Video Borescope for Precise Inspections

- Pipe Inspection Borescope

- Measurement Borescope

- Probe of Borescope

- Stereo Microscope

- Biological Microscope

- Metallurgical Microscope

- Fluorescence Microscope

- Polarization Microscope

- Digital Microscope

- Multi-viewing Microscope

- Comparison Microscope

- Electronic Eyepieces

- Illumination

- Protable Microscope

- Magnifying Fluorescent

- Thermal Camera

Stainless Steel spring tube provides inspection flexibility / Rubbing resistant material pipe, increase of service life.

Easy to pass through sharp curves.

-

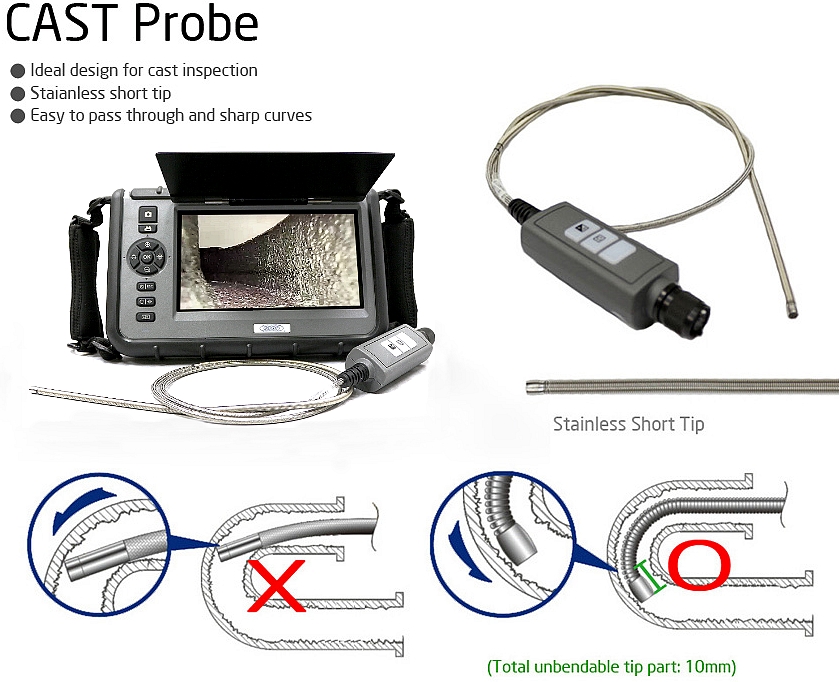

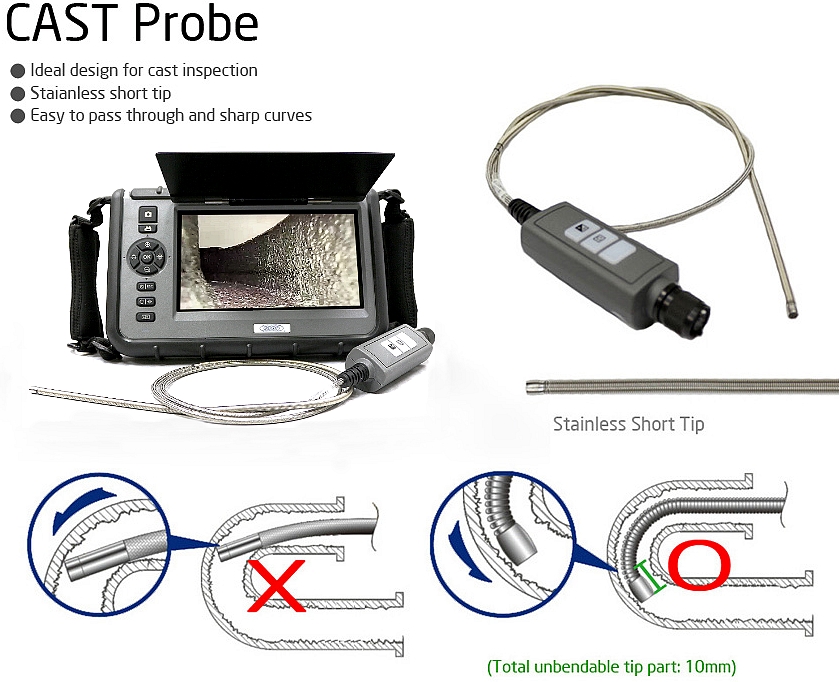

CAST Probe

Ideal Design For Cast Inspection

Stainless Short Tip

Easy To Pass Through And Sharp Curves

RESILIENT SPRING PROBE

IDEAL FOR CAST INSPECTION

**Cast Inspection Spring Flexible VGA Probe (J Series): Precision Unleashed for Casting Inspection**

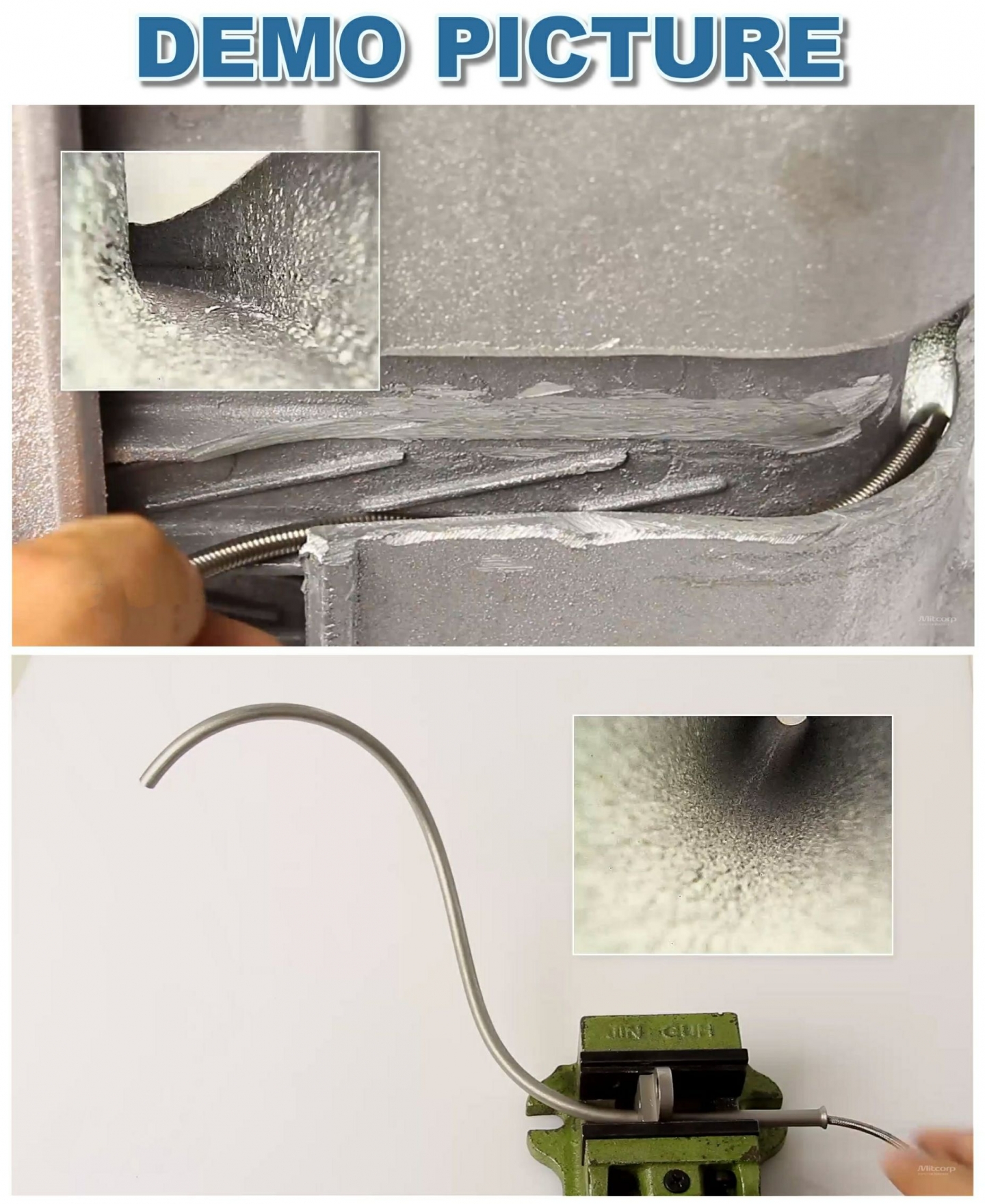

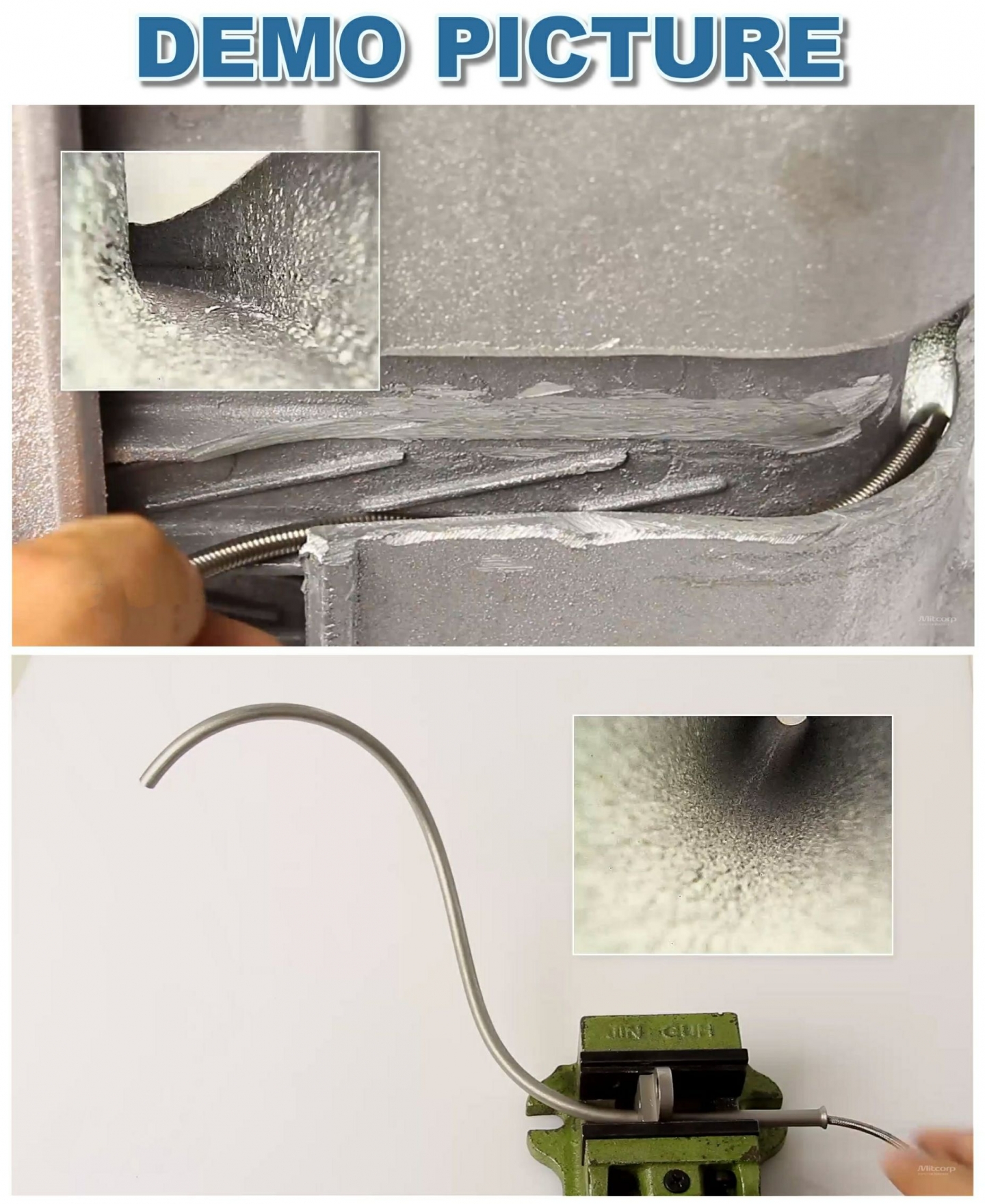

The Cast Inspection Spring Flexible VGA Probe (J Series) is meticulously crafted for casting inspection scenarios, delivering exceptional performance. Equipped with a stainless steel short tip, this probe is designed to effortlessly navigate through narrow spaces and sharp bends, providing an ideal solution for intricate inspection tasks.

A key advantage of the flexible spring probe is its resilience, making it particularly well-suited for casting inspection tasks, ensuring precision in identifying potential issues or defects. Whether inspecting cast components in an industrial setting or performing quality control checks, this probe offers outstanding reliability.

Invest in the Cast Inspection Spring Flexible VGA Probe (J Series), a cutting-edge tool that combines innovative design with powerful functionality. It proves to be an invaluable asset for professionals involved in casting inspection processes. -

Features Description Tip Diamete Ø 5.4 mm Camera Length 7mm Camera Material Stainless Steel Probe Material Stainless Steel Spring Probe Diamete Ø 4.5 mm F.O.V 90° D.O.F. 10 mm ~ 100 mm Resolution 640 X 480 ( VGA ) Working Temperature -10°C ~ 60°C Light Source White LED * 5 Probe Length 1M Waterpoof IP67 Function Brighter Image, Rotation Image -

JK Main Console System

‧ Large 7" HQ LCD Monitor (800*480)

‧ Snapshot & Video Recording with Audio (640*480)

‧ LED brightness adjustment

‧ Mirror Image & Image Rotation

‧ 5X Zoom In ( 1.5X / 2.0X / 5.0X )

‧ USB to PC Conneciotn

‧ Live View Software to PC

‧ Long duty hour up to 6 hrs

‧ 1 meter drop test

‧ Waterproof and dustproof grade IP 55

JF Main Console System

‧ 3.5" TFT LCD Monitor (320*240)

‧ Snapshot & Video Recording (640*480)

‧ LED brightness adjustment

‧ 2X Zoom In & Mirror Image

‧ USB to PC Conneciotn -

Model Type of Probe Tip Dia. Length Material of Tube Console System JKVS-5401 Cast Probe Ø 5.4mm 1M Stainless Steel Spring 7" Monitor JFVS-5401 Cast Probe Ø 5.4mm 1M Stainless Steel Spring 3.5" Monitor -

COMMON CASTING DEFECTS AND DISCONTINUITIES

-

Surface defects

A rough surface defect. Surface defects are visible to an inspector. These include very rough or uneven surfaces; “veins” or “rat tails” caused by cracking of the mold at high temperatures; “elephant skin,” which is puckered due to quick cooling; burned sand; and stripping defects. Stripping defects are flakes of metal on the surface caused by gas being trapped in the mold.

-

Inclusion defects

- Slag inclusion is a defect where non-metallic materials create pockets or ribbon-like entrainments in the casting. Slag is an important part of the melting process in the furnace, necessary for good quality castings, as chemical processes in silica and calcium-based slags change the viscosity of the metal. During pouring, however, the foundry worker must keep slag out of the mold itself. Just before pouring, slag is often skimmed, but not all the slag is be captured at this stage. The sprue or gates of the mold also need to be formed to capture it. Failures at any step in this process may allow slag to contaminate the metal. Further, oxidization of the metal can be a problem for metals that have stayed at high temperatures a long time; slag can form inside the mold. Oxides are not the only slag: carbides, sulfides, or nitrides can also be at fault.

- Sand inclusion is very common. It is expected in small quantities at surface depths for all sand castings. However, too much sand inclusion can ruin a casting. In this defect, sand from the mold gets trapped in the metal.

If there is a lot of sand inclusion at the surface, it might indicate the need for a mold wash, or a different molding system. In foundry sand that has been baked for stability, perhaps the mold spent too long in the oven and became fragile. Perhaps a better choice would be no-bake molding or an investment casting. This defect may also suggest there was not enough binder, or not the right kind of binder, to create a strong shell. Another possibility is that the sand was insufficiently packed.

-

Molding and pouring defects

This small discontinuity is a misrun. - Underpour or misrun defects happen when not enough molten metal has been introduced to fill the mold. Sometimes, open risers are used to judge when a mold is full: if they are misplaced, the casting might be short poured. Sometimes, misruns are caused by early freezing during the pour. In misruns, some part of the casting is incomplete, usually with a rounded edge where the metal froze before it reached the mold’s wall.

- A raised mold or floating core will cause the casting to have the wrong dimensions. Molten metal exerts pressure, and if the core is not stabilized or mold properly clamped down, they can lift, deforming the casting.

- Flashing at joins is common in castings but must be removed. Flashing is a thin skin created when liquid metal seeps between closed joints on the mold. If there is instability in the mold, flashing can be bad enough to deform the casting.

- Mold mismatch or mold shift can happen if the cope and drag, or top and bottom of the mold are misaligned when it is closed. The resulting casting is often comical, as the top and bottom parts of the mold are askew.

-

Mold instability destroys fine details. Sand instability, insufficient packing, or issues with the foundry sand mixture can cause a loss of detail on a casting. This issue can affect fine details, like letters or decorations, or can lead to wavering edges over the whole casting.

- Cold lap or cold shuts happen when the temperature of the mold or of the molten material is too low. Rather than flowing quickly throughout the mold, part of the stream of metal slows and begins to harden. This freezing bulge becomes an obstacle that the rest of the metal eddies around: like a rock in the river, there is often a disturbance on the down-stream side of the obstacle. The visible round lip of the cold lap creates a permanent discontinuity in the surface of the casting. This defect is visible on the surface, and sometimes is small enough to be ground or filled, but a cold shut or lap can go deep enough to threaten the structural integrity of the casting.

- Cold shots, similarly, are caused by the premature freezing of some of the metal. They look like little iron balls or teardrops that are held, suspended, in the material around them.

-

Holes due to gas porosity. Pinholes and blowholes or gas porosity can be caused by gas in the mold pushing through the molten metal leaving voids or bubbles as it cools. Trapped gas can be caused by the conditions of the mold, if it’s not porous enough to allow gas escape. Rusty, hydrogen rich charges of scrap metal are more likely to cause pinhole defects as they bring more hydrogen with them.Gas porosity is different than shrinkage porosity, although both leave small holes in the casting and can be found in the same piece of metal. Gas porosity tends to leave regular, bubble shaped pinholes near the top of the mold.

-

-

Introduction

CAST Probe

Ideal Design For Cast Inspection

Stainless Short Tip

Easy To Pass Through And Sharp Curves

RESILIENT SPRING PROBE

IDEAL FOR CAST INSPECTION

**Cast Inspection Spring Flexible VGA Probe (J Series): Precision Unleashed for Casting Inspection**

The Cast Inspection Spring Flexible VGA Probe (J Series) is meticulously crafted for casting inspection scenarios, delivering exceptional performance. Equipped with a stainless steel short tip, this probe is designed to effortlessly navigate through narrow spaces and sharp bends, providing an ideal solution for intricate inspection tasks.

A key advantage of the flexible spring probe is its resilience, making it particularly well-suited for casting inspection tasks, ensuring precision in identifying potential issues or defects. Whether inspecting cast components in an industrial setting or performing quality control checks, this probe offers outstanding reliability.

Invest in the Cast Inspection Spring Flexible VGA Probe (J Series), a cutting-edge tool that combines innovative design with powerful functionality. It proves to be an invaluable asset for professionals involved in casting inspection processes. -

Specification

Features Description Tip Diamete Ø 5.4 mm Camera Length 7mm Camera Material Stainless Steel Probe Material Stainless Steel Spring Probe Diamete Ø 4.5 mm F.O.V 90° D.O.F. 10 mm ~ 100 mm Resolution 640 X 480 ( VGA ) Working Temperature -10°C ~ 60°C Light Source White LED * 5 Probe Length 1M Waterpoof IP67 Function Brighter Image, Rotation Image -

Console System

JK Main Console System

‧ Large 7" HQ LCD Monitor (800*480)

‧ Snapshot & Video Recording with Audio (640*480)

‧ LED brightness adjustment

‧ Mirror Image & Image Rotation

‧ 5X Zoom In ( 1.5X / 2.0X / 5.0X )

‧ USB to PC Conneciotn

‧ Live View Software to PC

‧ Long duty hour up to 6 hrs

‧ 1 meter drop test

‧ Waterproof and dustproof grade IP 55

JF Main Console System

‧ 3.5" TFT LCD Monitor (320*240)

‧ Snapshot & Video Recording (640*480)

‧ LED brightness adjustment

‧ 2X Zoom In & Mirror Image

‧ USB to PC Conneciotn -

Model

Model Type of Probe Tip Dia. Length Material of Tube Console System JKVS-5401 Cast Probe Ø 5.4mm 1M Stainless Steel Spring 7" Monitor JFVS-5401 Cast Probe Ø 5.4mm 1M Stainless Steel Spring 3.5" Monitor -

Optional Accessory

-

Q&A

COMMON CASTING DEFECTS AND DISCONTINUITIES

-

Surface defects

A rough surface defect. Surface defects are visible to an inspector. These include very rough or uneven surfaces; “veins” or “rat tails” caused by cracking of the mold at high temperatures; “elephant skin,” which is puckered due to quick cooling; burned sand; and stripping defects. Stripping defects are flakes of metal on the surface caused by gas being trapped in the mold.

-

Inclusion defects

- Slag inclusion is a defect where non-metallic materials create pockets or ribbon-like entrainments in the casting. Slag is an important part of the melting process in the furnace, necessary for good quality castings, as chemical processes in silica and calcium-based slags change the viscosity of the metal. During pouring, however, the foundry worker must keep slag out of the mold itself. Just before pouring, slag is often skimmed, but not all the slag is be captured at this stage. The sprue or gates of the mold also need to be formed to capture it. Failures at any step in this process may allow slag to contaminate the metal. Further, oxidization of the metal can be a problem for metals that have stayed at high temperatures a long time; slag can form inside the mold. Oxides are not the only slag: carbides, sulfides, or nitrides can also be at fault.

- Sand inclusion is very common. It is expected in small quantities at surface depths for all sand castings. However, too much sand inclusion can ruin a casting. In this defect, sand from the mold gets trapped in the metal.

If there is a lot of sand inclusion at the surface, it might indicate the need for a mold wash, or a different molding system. In foundry sand that has been baked for stability, perhaps the mold spent too long in the oven and became fragile. Perhaps a better choice would be no-bake molding or an investment casting. This defect may also suggest there was not enough binder, or not the right kind of binder, to create a strong shell. Another possibility is that the sand was insufficiently packed.

-

Molding and pouring defects

This small discontinuity is a misrun. - Underpour or misrun defects happen when not enough molten metal has been introduced to fill the mold. Sometimes, open risers are used to judge when a mold is full: if they are misplaced, the casting might be short poured. Sometimes, misruns are caused by early freezing during the pour. In misruns, some part of the casting is incomplete, usually with a rounded edge where the metal froze before it reached the mold’s wall.

- A raised mold or floating core will cause the casting to have the wrong dimensions. Molten metal exerts pressure, and if the core is not stabilized or mold properly clamped down, they can lift, deforming the casting.

- Flashing at joins is common in castings but must be removed. Flashing is a thin skin created when liquid metal seeps between closed joints on the mold. If there is instability in the mold, flashing can be bad enough to deform the casting.

- Mold mismatch or mold shift can happen if the cope and drag, or top and bottom of the mold are misaligned when it is closed. The resulting casting is often comical, as the top and bottom parts of the mold are askew.

-

Mold instability destroys fine details. Sand instability, insufficient packing, or issues with the foundry sand mixture can cause a loss of detail on a casting. This issue can affect fine details, like letters or decorations, or can lead to wavering edges over the whole casting.

- Cold lap or cold shuts happen when the temperature of the mold or of the molten material is too low. Rather than flowing quickly throughout the mold, part of the stream of metal slows and begins to harden. This freezing bulge becomes an obstacle that the rest of the metal eddies around: like a rock in the river, there is often a disturbance on the down-stream side of the obstacle. The visible round lip of the cold lap creates a permanent discontinuity in the surface of the casting. This defect is visible on the surface, and sometimes is small enough to be ground or filled, but a cold shut or lap can go deep enough to threaten the structural integrity of the casting.

- Cold shots, similarly, are caused by the premature freezing of some of the metal. They look like little iron balls or teardrops that are held, suspended, in the material around them.

-

Holes due to gas porosity. Pinholes and blowholes or gas porosity can be caused by gas in the mold pushing through the molten metal leaving voids or bubbles as it cools. Trapped gas can be caused by the conditions of the mold, if it’s not porous enough to allow gas escape. Rusty, hydrogen rich charges of scrap metal are more likely to cause pinhole defects as they bring more hydrogen with them.Gas porosity is different than shrinkage porosity, although both leave small holes in the casting and can be found in the same piece of metal. Gas porosity tends to leave regular, bubble shaped pinholes near the top of the mold.

-